Precision Thermoforming for Medical Packaging: Trusted Experts in Custom Solutions

Specialized Cleanroom Thermoforming for Medical Packaging Needs – From Prototypes to Full Production

Your Trusted Partner for Innovative Medical Packaging Solutions

We will beat your existing medical packaging price.

We will cover the cost of tooling for purchases exceeding $150,000 per year, or for long-term agreements.

Our Quick Changeover technology enables us to deliver you low volume high mix offerings.

All parts are manufactured in North America eliminating the need for long and unreliable supply chains.

Medical packaging

Cleanroom Thermoformed Medical Packaging

Do you wish that your medical packaging was manufactured with absolute precision? Every detail is handled by specialists who live and breathe thermoforming for the medical industry?

That’s the Southmedic difference.

As specialists in thermoforming for medical packaging, we’ve mastered the art of turning complex requirements into flawless, functional solutions. And we do it all within a state-of-the-art cleanroom environment that meets the highest industry standards.

Why Does That Matter?

Because when you’re an engineer developing the next breakthrough in medical technology, you need packaging that’s as precise and reliable as the device itself. And when you’re a buyer tasked with finding a new vendor, you need a partner who can deliver consistency, quality, and peace of mind—every single time.

At Southmedic, we don’t just get your needs—we anticipate them. Our team of experts is ready to take on your most challenging projects, offering custom solutions that align perfectly with your specifications and timelines. From initial concept to final production, we ensure your medical packaging is nothing short of perfection.

When you choose Southmedic, you’re choosing a level of expertise that’s unmatched in the industry. You’re choosing a partner who knows that in the world of medical packaging, there’s no room for error. And most importantly, you’re choosing a company that’s as committed to finding a better way as you are.

Thermoformed Packaging for Medical Devices

There’s a Better Way

Frustrated with your current medical packaging provider? Tired of dealing with inconsistent quality, delayed timelines, or materials that just don’t meet compliance standards?

The risks are real. Subpar packaging can lead to delayed product launches, compliance headaches, and even put patient safety at risk. Can you afford to take that chance?

There’s a better way: Southmedic’s cleanroom thermoforming services deliver reliable, compliant, and high-quality packaging solutions tailored to your exact needs. Say goodbye to the stress and hello to peace of mind.

Upgrade your packaging without breaking your budget with Southmedic Thermoform Medical Device Packaging.

Why Choose Southmedic for Thermoformed Medical Packaging?

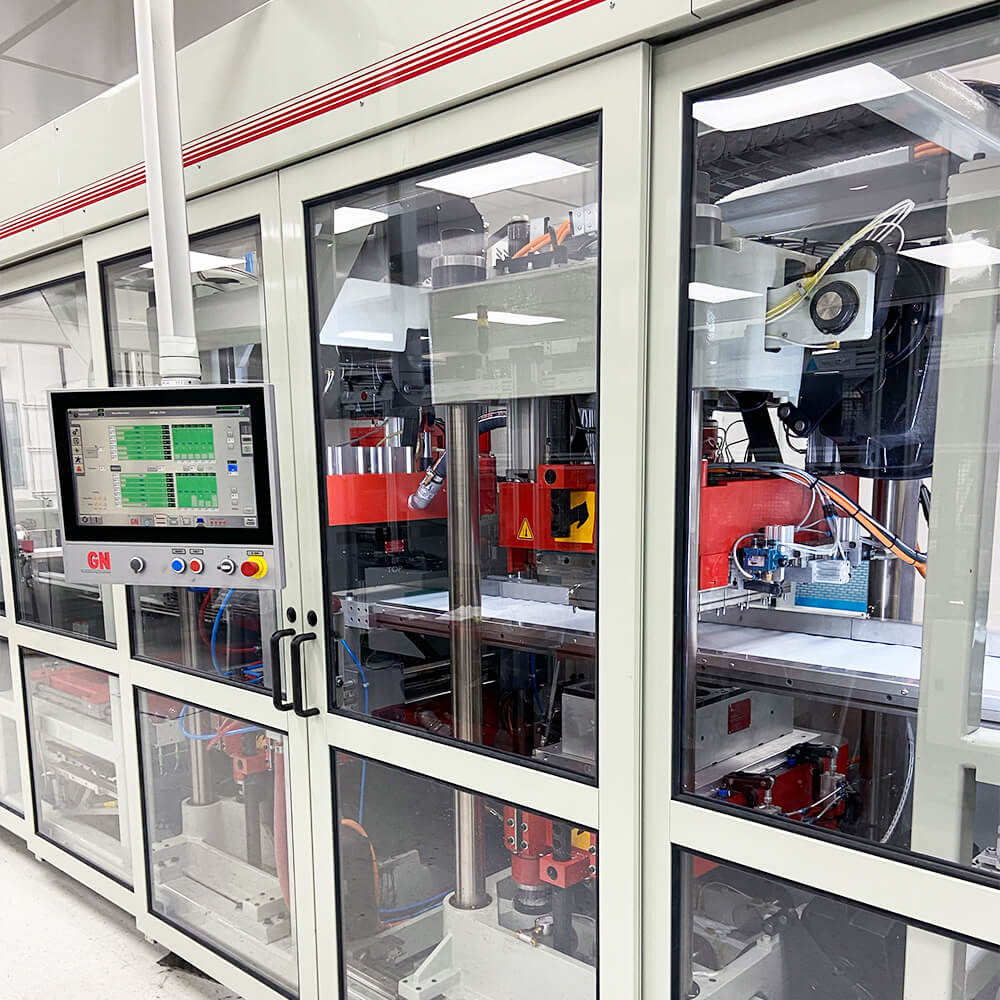

Cleanroom Environment

Cleanroom environment ensuring the highest standards of hygiene and compliance.

Customizable Solutions

Customizable solutions tailored to specific packaging needs, including material choice and design.

Expertise

Expertise in rapid development and prototyping for engineers and manufacturers.

Advanced Systems

Advanced Form, Trim, and Stack inline systems with third motion capabilities for precision and cost efficiency.

Industry-Specific Medical Packaging Thermoforming Expertise

Our cleanroom environment is key for medical packaging because it ensures that your products are manufactured in a highly controlled and contamination-free setting. In the medical industry, even the smallest particles of dust, bacteria, or other contaminants can compromise the safety and effectiveness of medical devices and packaging. Our cleanroom environment maintains strict control over air quality, temperature, humidity, and particulate levels, which helps to prevent any contamination during the manufacturing process.

This level of cleanliness is essential for meeting stringent industry standards, including those required by regulatory bodies like the FDA. It also ensures that your packaging will not introduce any impurities or pathogens that could endanger patient safety. In essence, a cleanroom environment guarantees the highest level of product integrity and reliability, which is critical in the medical field where the stakes are exceptionally high.

In addition, our entire thermoforming process is designed to create high-quality, custom medical packaging with precision and reliability. The process begins with the selection of top-tier materials, all of which meet stringent sterilization, safety and compliance standards. These materials are carefully chosen to ensure that the packaging not only protects medical devices but also withstands the demanding conditions of the healthcare environment.

Our thermoforming process itself is highly efficient, offering significant advantages for medical packaging. It allows for cost-effective customization, meaning that packaging can be tailored specifically to the needs of each product without incurring exorbitant costs. Additionally, the tooling costs associated with thermoforming are lower compared to other methods, making it an economical choice for both small and large production runs. This, coupled with faster lead times, means that products can get to market more quickly—an essential factor in the fast-paced medical industry.

Our Medical Devices Are Trusted Worldwide

Southmedic medical devices, equipment and products are trusted and considered the gold standard around the world.

Thermoformed Packaging for Medical Devices

Certifications and Compliance

-

MDSAP 675962 – ISO 13485:2016

QUALITY MANAGEMENT SYSTEM – ISO 13485:2016 -

CE 644824 – Annex V

EC CERTIFICATE – PRODUCTION QUALITY ASSURANCE -

MDEL 420

MEDICAL DEVICES ESTABLISHMENT LICENCE LISTING -

FM 643600 – ISO 13485:2016

QUALITY MANAGEMENT SYSTEM – ISO 13485:2016 -

CE 644823 – Annex II

EC CERTIFICATE – FULL QUALITY ASSURANCE SYSTEM

Get a Free Quote on Custom Thermoforming Solutions

Ready to Transform Your Medical Packaging?

Get the Best Value for Your Medical Packaging – We’ll Beat Any Quote! Contact Us Today for a Custom Thermoforming Solution.

Or Call Us Directly at 1-705-720-1902 to Discuss Your Project.